By: Kathryn Noble

In labs, workshops, and startups around the globe, something remarkable is unfolding: machines are beginning to print not just objects, but functions. A new generation of 3D printed devices is emerging, ones that don’t just sit still but sense, move, respond, and compute. This is the frontier where mechanical engineering meets electronics, and boundaries begin to blur.

Functional 3D printed devices refer to components created through additive manufacturing that perform active roles—such as sensing temperature, transmitting data, or executing programmed behavior—without requiring additional assembly or external circuitry. They are not prototypes of how a product will look, but working prototypes of what a product can do.

At the heart of this movement lies a powerful convergence: embedded electronics meeting customized mechanical design in a single manufacturing process. This is more than just innovation in hardware, it’s a reimagining of how we prototype, test, and manufacture across industries.

What does it mean to “bridge the gap” between electronics and mechanics?

For decades, mechanical and electrical design followed parallel paths, rarely crossing until final assembly. Engineers worked in silos: one group focused on mechanical structures, another on circuits and firmware. Integration was manual, messy, and prone to misalignment.

Bridging this gap means merging mechanical form and electronic function into a single, seamless build. No more designing housings for PCBs or routing wires around actuators. Instead, designers aim to fabricate fully integrated, functional systems, straight from the printer.

This shift isn’t just about convenience. It represents a fundamental leap in how things are made.

Barriers that once kept electronics and mechanics separate included:

- Different manufacturing processes

- Material incompatibilities

- Assembly complexity

- Design-to-manufacture delays

Today, innovations in 3D printing are dissolving these barriers, giving engineers the tools to unify form and function from the ground up.

What are functional 3D printed devices?

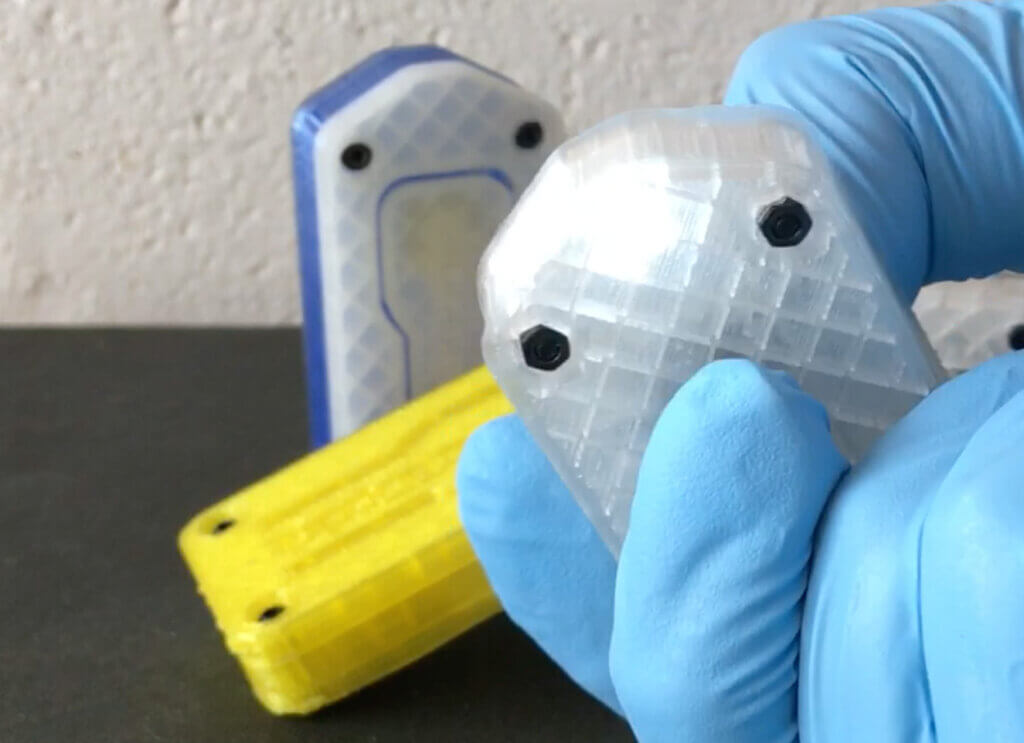

Functional 3D printed devices are not static models or cosmetic shells. They are active, working components capable of performing specific physical or electronic tasks. These devices often combine mechanical structures with electronic behaviors—resulting in parts that move, sense, compute, or interact with their environment.

Key features typically include:

- Embedded sensors and actuators

- Internal wiring and circuitry

- Conductive pathways

- Programmable or responsive behaviour

This convergence allows manufacturers to create devices that are smart, responsive, and often customized to niche applications.

Examples of functional 3D printed devices include:

- Wearable sensors for biometric tracking

- Soft robotics with embedded actuators

- IoT-enabled housings with integrated antennas

- Custom-shaped embedded RF systems

- Personalized medical implants with diagnostic feedback

These examples show how far beyond static printing the technology has advanced—creating devices that don’t just exist, but act.

How has additive manufacturing evolved to support electromechanical integration?

For 3D printing to enable such sophisticated integration, the technology itself had to evolve. Early printers were limited to simple thermoplastics, focused only on shape and structure. Now, advanced printers support conductive inks, flexible polymers, and hybrid materials, enabling a new design paradigm where function is printed layer by layer.

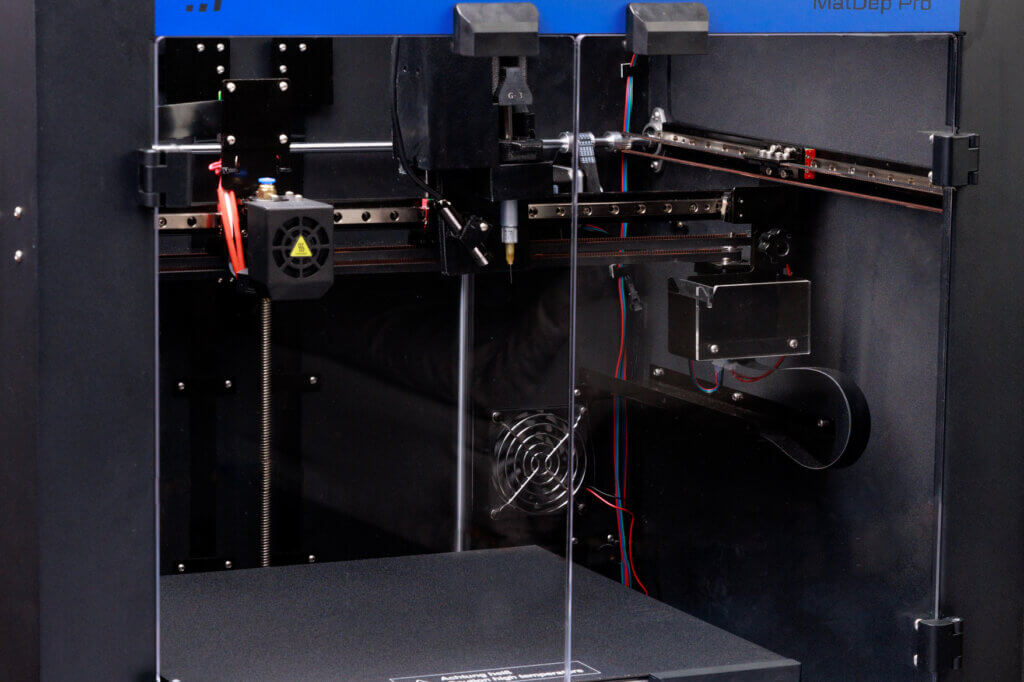

Key developments in material extrusion 3D printing include the rise of multi-material extrusion, where conductive and structural materials are printed in tandem. Innovations in multi-axis printing allow for more complex geometries and embedded features. Post-processing has also advanced, with built-in curing, sintering, or lamination steps bringing printed circuits to life.

Technological breakthroughs driving this shift:

- Multi-material extrusion systems

- Inkjet and aerosol jet deposition for conductive layers

- Integrated post-processing (UV curing, sintering)

- Conductive pastes and printed wiring embedded mid-print

Each innovation expands what’s possible in electromechanical design, collapsing what once took multiple supply chains into a single machine.

What are the main technologies used to 3D print functional electromechanical parts?

3D printing functional electronics requires specialized methods that go beyond traditional filament extrusion. Each method brings its own strengths, limitations, and ideal use cases.

Fused Deposition Modeling (FDM) with Conductive Filaments

FDM printers extrude thermoplastics through heated nozzles. When paired with conductive filaments—typically carbon- or graphene-filled—they can create basic circuits and conductive paths.

- Pros: Affordable, accessible, widely available

- Cons: Limited conductivity, low resolution, not suitable for high-frequency signals

Direct Ink Writing (DIW) and Paste Extrusion

DIW printers uses pressure-driven extrusion to deposit viscous materials like conductive inks, epoxies, or pastes. Ideal for printing flexible circuits or stretchable conductors.

- Pros: High viscosity tolerance, suitable for soft electronics

- Cons: Slow, complex calibration, may require post-curing

Inkjet Printing for Electronics

Inkjet printing deposits tiny droplets of conductive or dielectric ink in precise patterns, often on flexible or curved substrates.

- Pros: High resolution, great for microelectronics

- Cons: Requires fine-tuned materials, sensitive to environmental conditions

Selective Laser Sintering (SLS) and Multi-material Variants

SLS fuses powdered materials using a high-powered laser, building objects layer by layer. While traditionally used for structural plastics, adaptations now allow for conductive powders and complex internal geometries.

- Pros: No support structures needed, great mechanical strength

- Cons: Expensive, limited conductive material options

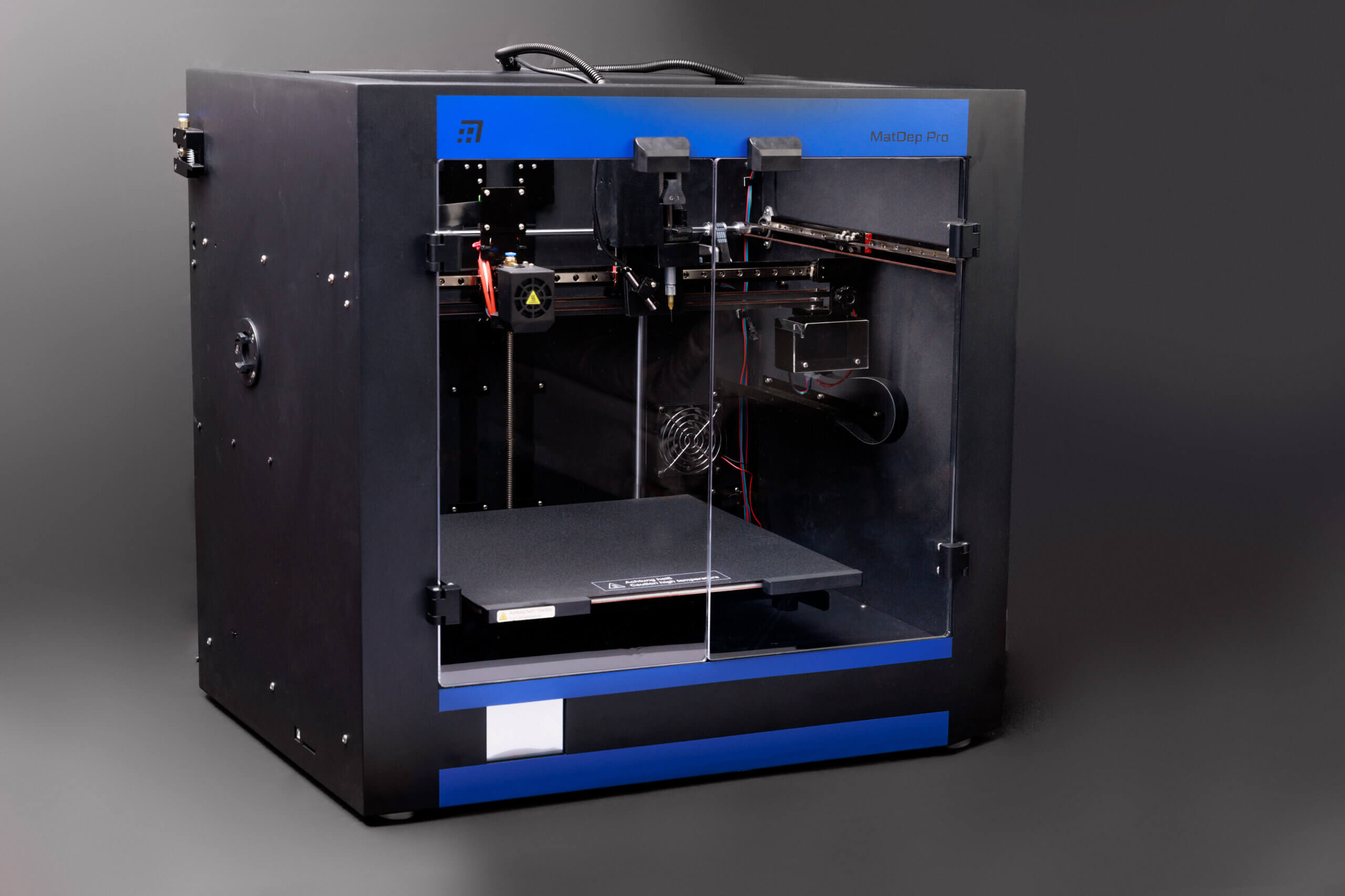

Hybrid 3D Printers (for Mechanical + Electrical Integration)

Hybrid systems include a combination of multiple technologies listed above with regards to electrical integration—allowing mechanical parts and electronic components to be fabricated or inserted in a single workflow.

- Pros: True integration of circuits and structure

- Cons: High cost, complex machine calibration

What materials are used for functional 3D printing of electronics and mechanics?

Material selection in 3D printing plays a pivotal role in functionality. For successful integration, each component—from conductor to insulator to substrate—must be carefully matched.

Conductive Materials

- Silver nanoparticle inks: High conductivity, used in antenna paths and circuits

- Carbon-filled filaments: Cost-effective for low-voltage applications

- Graphene-based pastes: Ideal for flexible or stretchable electronics

Dielectric and Insulating Materials

- UV-curable resins: Used for insulating circuit layers

- Polyimides: Excellent thermal resistance for high-power areas

- Flexible silicones: Provide separation between conductive paths

Structural Plastics and Flexible Polymers

- Nylon: Strong, SLS-compatible for load-bearing components

- TPU: Soft and flexible, often used in wearable designs

- ABS/PLA: Standard FDM materials for housings and mechanical support

Functional Inks and Nanocomposites

- Photopolymer composites: Enable electromechanical sensing

- Biosensor-embedded inks: Designed for medical diagnostic integration

How do you design for 3D printed electronics and mechanics integration?

Designing for integration requires a shift in mindset. It’s not just about geometry—it’s about sequencing, material overlap, and electrical continuity.

Key design considerations include:

- Layer-by-layer circuit routing

- Thermal isolation between components

- Tolerancing between moving and electronic parts

- Modular or embedded connectors

What are the most common design mistakes?

- Routing conductive paths too close → can cause shorts or interference

- Incompatible material overlaps → lead to delamination or failure

- No allowance for curing/shrinkage → results in dimensional instability

- Poor grounding layout → causes signal noise or device instability

What tools and software support electromechanical 3D design?

Modern CAD/EDA tools are evolving to meet the challenge. Platforms like Autodesk Fusion 360 with Eagle and Altium 365 software offer co-design capabilities—allowing mechanical and electronic elements to coexist within a single digital prototype.

They support:

- Circuit simulation

- Electromechanical constraint checking

- Layer alignment and embedded routing visualization

What industries are leading the adoption of functional 3D printed devices?

Aerospace and Defense

- Lightweight sensor housings

- Embedded antennas for communication

- Field-deployable diagnostics

Consumer Electronics

- Smart wearables with curved electronics

- Personalized gadget enclosures

- IoT sensor nodes

Medical and Biomedical Devices

- Custom implants with biosensors

- Smart drug delivery systems

- Low-volume prosthetic components

Automotive and Mobility

- Interior panels with embedded touch sensors

- Adaptive lighting enclosures

- Smart tire pressure monitoring prototypes

Industrial Automation and Robotics

- Robotic grippers with embedded sensors

- Onboard diagnostic modules

- Embedded strain and vibration monitors

Research and Academia

- Rapid prototyping of experimental devices

- Functional lab-on-chip models

- Educational tools for STEM learning

What are the benefits of 3D printing fully functional devices?

- Faster time to market

- Customization and personalization

- Assembly-free design

- Lightweight structures

- Design freedom

- Reduced electronic packaging size

What are the limitations and challenges of 3D printing functional devices?

- Limited electrical performance (vs. traditional PCBs)

- Material degradation and aging

- Lack of industry standards

- Integration with traditional manufacturing workflows

How do you prototype a functional 3D printed device?

- Concept and design

- Material selection

- Multi-material slicing and layout

- Set printing parameters

- Post-processing (e.g., curing, soldering)

- Testing and validation

What are the most common post-processing steps?

- UV curing

- Heat setting

- Mechanical finishing

- Electrical conductivity testing

- Soldering or conductive epoxy joining

Are these devices reliable and durable in real-world conditions?

Reliability is improving but still varies by application. Issues like material fatigue, electrical drift, and environmental exposure remain concerns. Researchers are developing benchmarks for mechanical-electronic stability and validating performance under stress, humidity, and vibration. Some prototypes now match traditional assemblies in mid-duty cycles—but widespread standards are still emerging.

What safety considerations apply to functional 3D printed devices?

- Electrical insulation

- Circuit overheating

- Proper grounding and shielding

- Material safety (toxicity, fumes)

- Structural failure risks

How do these devices fit into smart manufacturing and Industry 4.0?

Functional 3D printed devices enable real-time data acquisition through embedded sensors, driving smarter digital twins and predictive maintenance. For instance, integrated thermal sensors in robotic arms can detect overheating before failure. In smart factories, printed antennas and strain gauges feed performance data into AI systems, turning physical assets into information hubs.

What are the future trends in 3D printed electronics and functional integration?

- 4D printing (structures that change over time)

- Embedded AI and edge computing

- Self-healing circuits

- Recyclable conductive materials

- Flexible and stretchable electronics

Conclusion

Functional 3D printed devices are more than the next phase of prototyping—they’re the blueprint for how machines and materials will co-evolve. By combining electronics and mechanics in a single print cycle, engineers unlock new levels of design freedom, responsiveness, and complexity. From soft robots to smart implants, the line between form and function is blurring, and the future is actively being printed.

Written by: Kathryn Noble – PR at Raise 3D Technologies