A limited production run to make 50 MatDep Pro available to select customers via application

Burlingame, CA – nano3Dprint, a next-generation additive manufacturing solutions provider, today announced the launch of its exclusive MatDep Pro 3D multi-material and electronics printer. The MatDep Pro is ideal for innovators, engineers, entrepreneurs, tech leaders and advanced at-home designers. Starting today, 50 units will be available to select consumers via application.

With the largest build volume of all nano3Dprint’s systems (14.17 x 9.84 x 7.87 inches, 360 x 250 x 200mm), the MatDep (materials disposition) Pro is capable of creating electronics with dynamic or active properties, including conductivity, magnetism or responsiveness to stimuli, as well as devices with locally tailored composition, structure and properties. Materials can be used on various substrates to create electrical connections between components or to form patterns of electrodes, wires or traces and embed them within FDM designs.

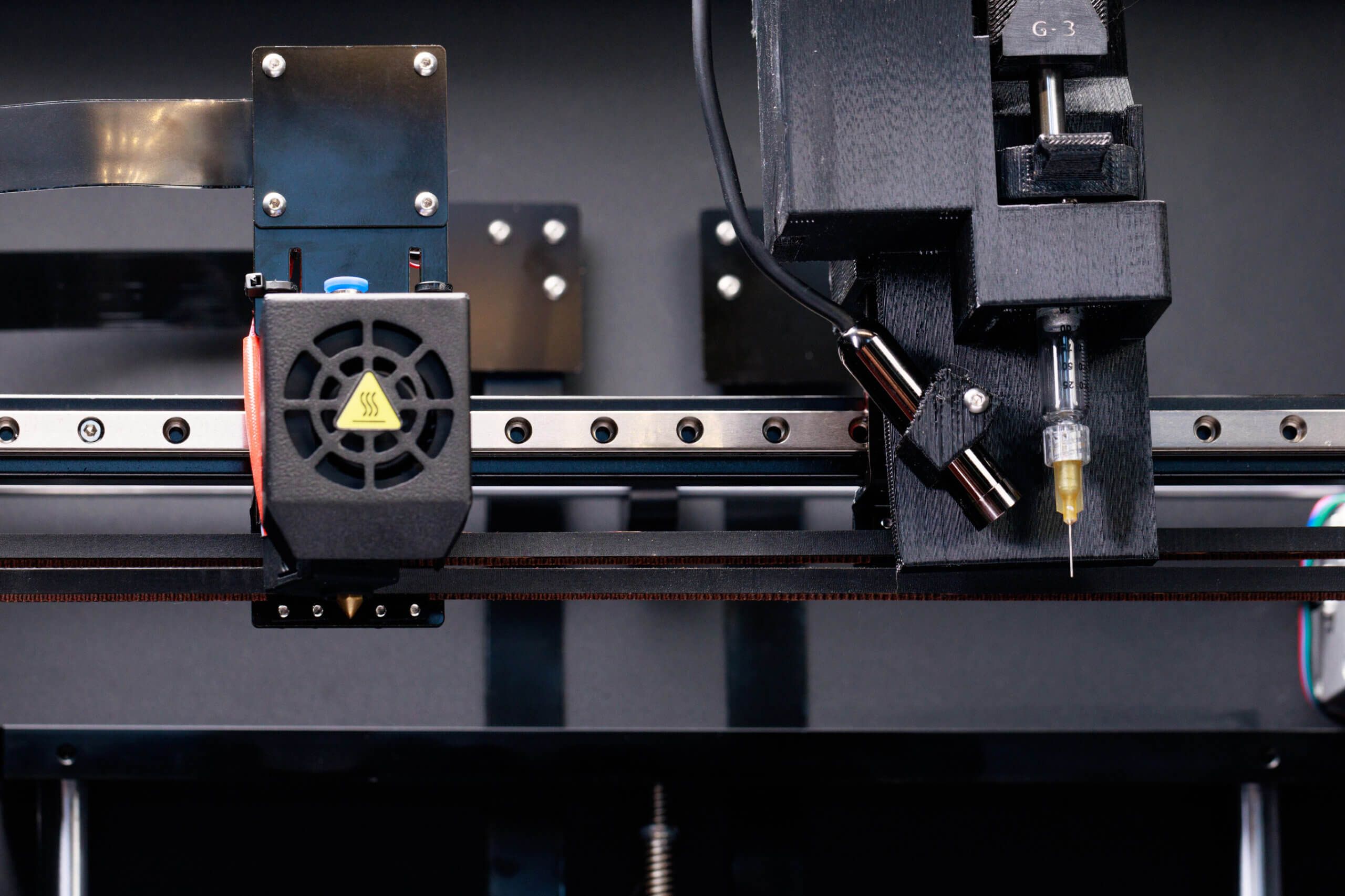

The MatDep Pro’s fused deposition modeling (FDM) extruder and materials dispensing system adds conductive and functional inks/pastes into a 3D design in a single pass. Users can print plastics (FDM materials like ABS and PLA) using the extruder while introducing advanced, highly conductive inks (gold, silver, etc.) and versatile pastes (silicone, polymers, etc.).

The extruder and materials dispensing system move independently, resulting in more precise and accurate prints. Ramsey Stevens, CEO of nano3Dprint, said that the MatDep Pro minimizes the amount of cross contamination, which is critical to avoid a short in the conductive path. “The independent motion of the print heads prevents cross contamination and offers better print quality, speed and reliability,” said Stevens.

MatDep Pro Features include an industrial linear guide, which yields stable and precise movement control; a flexible magnetic build mat for easy removal of finished prints; and nozzle cleaning stations for both the FDM extruder and the materials dispensing system. Further, the printer’s housing is made of steel construction, providing structural rigidity, less vibration and more precise print head movement.

“A major benefit of 3D printing with functional materials is creating electronics that can conform to different shapes and surfaces. This opens up new possibilities in wearable technology, smart textiles, biomedical devices or conformal supercapacitors, for example. Users can design and produce their own electronics on-demand, without the need for expensive and specialized equipment or facilities,” Stevens added.

The printer sells for $8,800 and requires a $500 refundable deposit. To learn more about the MatDep Pro, or fill out a purchase application, please visit the MatDep Pro webpage.

About nano3Dprint: nano3Dprint offers next-generation additive manufacturing solutions that enable printing of fully-realized electronic devices with seamless integration of micro-to-nanoscale materials. With its current electronics printer lineup, nano3Dprint is upleveling legacy 3D printing systems to allow users to invent, design, test, research and manufacture rapidly, easily and accurately.

Press contact:

Lauren Schiffman

PressFriendly

lauren@pressfriendly.com

###