Unleash Your Creativity: A Look at the nano3Dprint MatDep Pro and Its Endless Possibilities

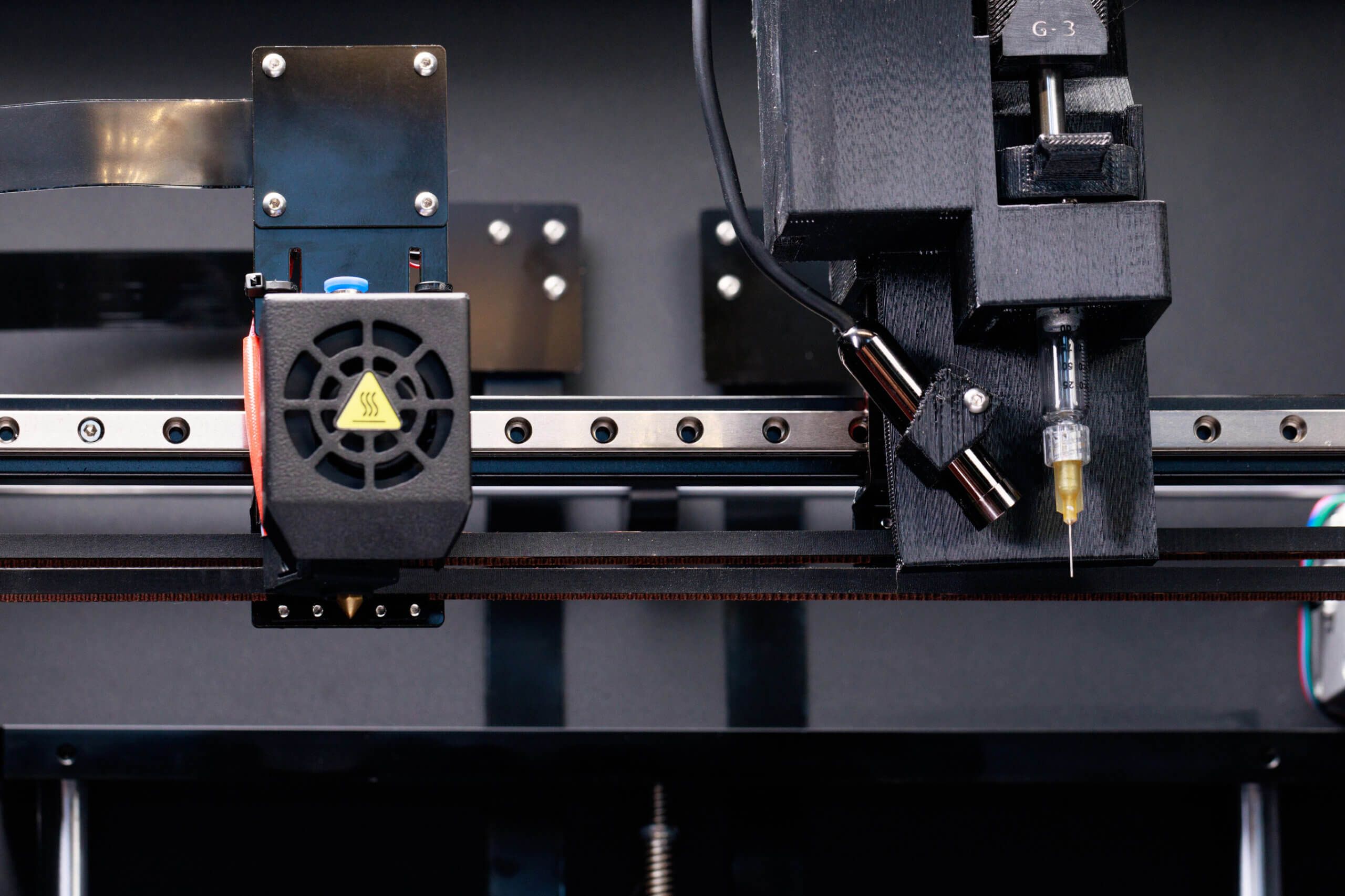

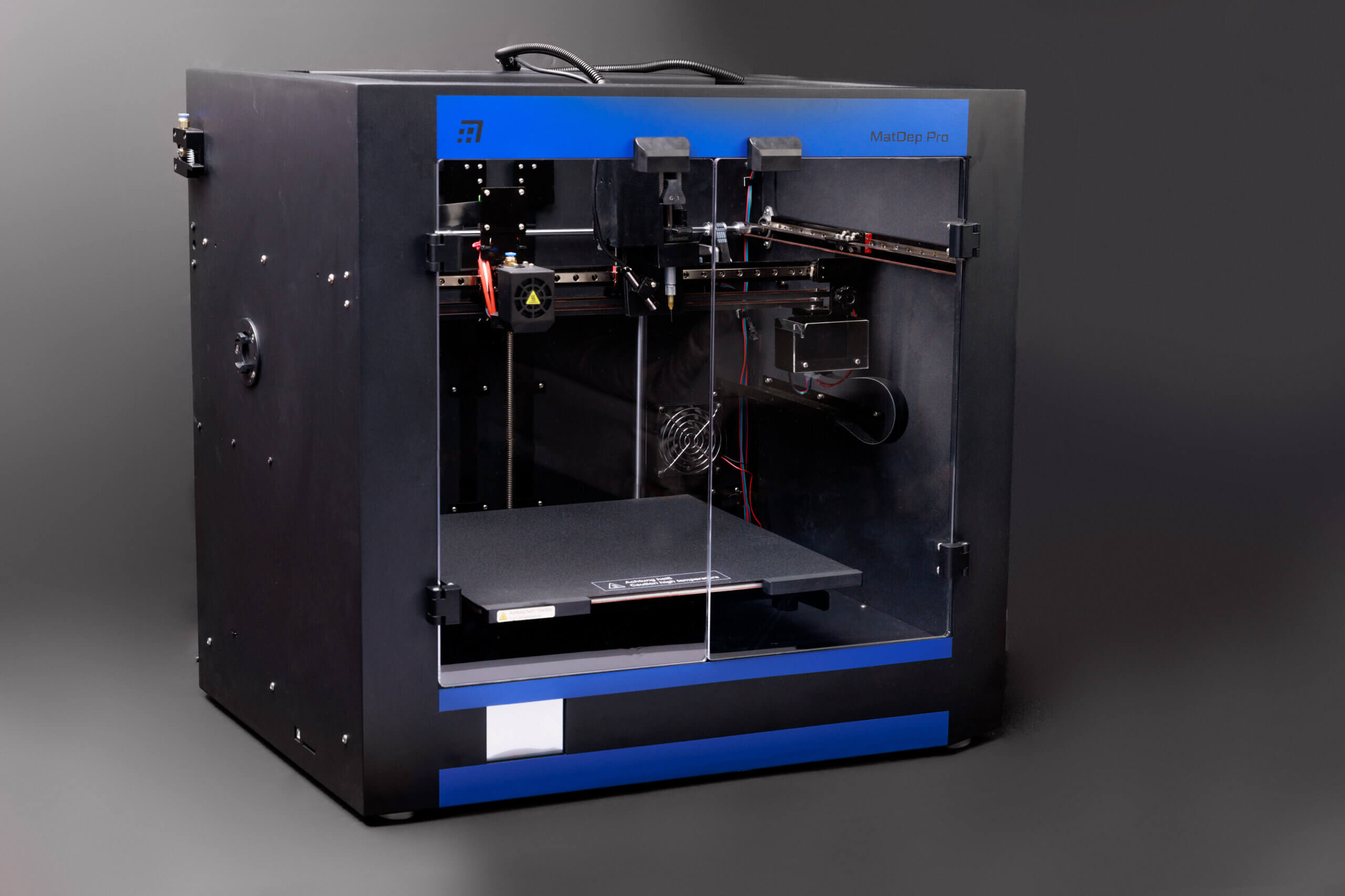

3D printing has revolutionized manufacturing, but what if you could not only create a physical object but also embed it with working electronics? That’s the power of the nano3Dprint MatDep Pro. This innovative 3D printer has two independent motion printheads. It combines a standard FDM (Fused Deposition Modeling) extruder with a materials dispensing system, allowing it to print with both traditional plastics and functional materials like conductive inks and pastes. The result? “Smart” objects with embedded circuitry, sensors, and more.

Here are some great ideas and applications for the nano3Dprint MatDep Pro, categorized by industry.

1. Consumer Electronics and Wearables

Imagine designing and printing custom electronics right from your desktop. The MatDep Pro makes this a reality. You can create a flexible, functional fitness tracker by printing the enclosure with TPU filament and then dispensing a conductive ink for the internal wiring. This “all-in-one” approach is also perfect for creating IoT (Internet of Things) devices with integrated Wi-Fi antennas or custom-fit enclosures for single-board computers like a Raspberry Pi.

2. Medical and Biomedical Devices

The ability to create custom, functional devices on-demand is a game-changer for the medical field. The MatDep Pro can be used to fabricate personalized prosthetic limbs with embedded pressure sensors or to produce unique diagnostic tools. It’s also ideal for rapid prototyping of specialized medical equipment, allowing researchers and clinicians to quickly test and iterate on new designs.

3. Robotics and Industrial Automation

In the world of robotics, the MatDep Pro can be used to create highly specialized components with built-in intelligence. You could print a soft robotic gripper with embedded conductive traces that act as sensors, giving the robot a sense of “touch.” This technology is also perfect for producing housings for industrial sensors or control systems with integrated wiring, simplifying assembly and improving overall reliability.

4. Research and Development / Academia

For innovators and students, the MatDep Pro is a powerful platform for learning and discovery. It streamlines the prototyping process by allowing you to create both the mechanical and electrical components of a new device in a single pass. Educators can use it to create interactive models that demonstrate complex concepts, like a model of a circuit that lights up, making STEM education more engaging and hands-on.

5. Other Novel Ideas

The possibilities extend far beyond these categories. The MatDep Pro is a great tool for the following as well.

Custom Printed Circuit Boards (PCBs): While not for mass production, the MatDep Pro can be used to quickly create small, customized PCBs for prototypes or for applications where a standard board wouldn’t fit.

Smart Packaging: Develop packaging for products with embedded electronics that can indicate freshness, temperature, or even track the location of the package.

Art and Design: Create interactive art pieces that light up or change based on touch or other stimuli, using both FDM materials for the structure and conductive inks for the electronics.

In summary, the MatDep Pro’s advantage is its ability to create a finished object with embedded electronics in a single, streamlined process. This “all-in-one” approach saves time, reduces assembly, and allows for designs that would be impossible with traditional manufacturing methods. The possibilities are limited only by the user’s imagination and access to functional materials.