In posts of the past, we’ve covered an assortment of topic related to 3D printing, 3D rapid prototyping, and 3D printer uses. We’ve looked at bio-printing organs, printable electronics and the world of automobiles and transportation, bees and 3D printing, and before that we also covered some precepts of 3D printing methodology.

We’ve also touched on some more surface-level, entertaining topics, like seven of the strangest things ever 3D printed, for example. With that variety of topics addressed in mind, we are going to continue with our theme of miscellaneousness today by taking a brief look at 3D printing and food production. For all of you Star Trek fans out there, yes, we are essentially talking about replicators. Although, be warned, we haven’t quite reached those technological heights just yet. All that to say you should continue reading if you are interested in learning about the progress and limitations of 3D printing edible objects.

How It Works

When we talk about 3D printing food, it doesn’t quite mentally click, as a term. It sounds strange, and it is. It’s not really any different the the printing of a toy or some other typical object. The only difference is in the raw material used in the process. In the case of manufacturing food, administrators need only take an edible paste and place it into the designated printer. Then the 3D printer deposits layer after layer of the tasty (hopefully) treat, until it’s ready to eat! While that is an oversimplification of the intricacies of the process of 3D printing, it’s not unfair to say that the 3D printing of edible goods is fundamentally similar to other categories of 3D printing. And while It’s not quite as fast as Captain Pickard made it look, but hey, it’s a start.

The Future Of Food?

Some see 3D printing as the key to the future of food production on a global scale. When you think about the value of being able to synthetically produce edible goods, the daunting topic of global hunger becomes a bit more manageable, at least in theory. There are many companies out there who are on the front lines of developing, and refining, this kind of technology. Among them are some heavy hitters, with Columbia University, NASA, and the European Union all being involved in the R&D of 3D food production to varying degrees.

One such company is the Netherlands Organization for Applied Scientific Research in Germany. They are taking the theory that printers could utilize hydrocolloids (substances which combine with water to become a gel) to replace base ingredients which are much more expensive than the proposed alternatives. The alternatives are plentiful in nature; algae, duckweed, grass, and the like. Things we won’t run out of any time soon, in all likelihood. But back to the Dutch research team based in Germany. They have successfully developed a printing method for microalgae, which is rich in protein, antioxidants, and carbohydrates. That is an exciting prospect for humanity, given that by 2050 we are projected to have over 9 billion mouths to feed.

What Can Be Printed?

The startup Natural Machines has made a 3D food printer called the Foodini (love it) which is “A new generation kitchen appliance that combines technology, food, art, and design.” That’s pretty great right there. Although the Foodini has still yet to be released, signs are encouraging, from an aesthetic perspective at the least. Which is to say, it looks like food we’d eat.

Foodini comes with empty food capsules and basic ingredients for a range of foods and recipes. According to Natural Machines themselves, they believe their niche lies in replacing packaged food that you normally would have to either buy frozen or spend the time to hand-make. Ravioli, breadsticks, and pretzels are all examples of the Foodini’s fortè, as provided by Natural Machines.

But the Foodini doesn’t stop there. In an interview with the Observer, Natural Machine’s co-founder and CMO, Lynette Kucsma, had this to say about the scope of functionality the Foodini possesses, “You can absolutely do things that are not possible by hand but you can also do customized nutrition in even boring square shapes like crackers. What we can do with 3D food printing is you can actually deconstruct a lot of those recipes and then reconstruct them with the 3D food printing that’s customized for you, in terms of nutrition.”

Lynette goes on to talk about the prospects of 3D food printing in reference to its utilization in outer space. “…it’s an automation tool. That’s where it’s going. I think it’s going to help in space exploration so when we deconstruct those foods, the way you deconstruct them can also be used in space”. The concept of 3D printing objects in space in a fascinating one, and probably one that is best left for a future post. But the prospect of being able to greatly increase our efficiency in a variety of ways, one of them being in nutritional production, is an encouraging one.

Obstacles And Limitations

3D printing food is time consuming. Ingredients interact with each in complex ways from a chemical perspective, and that makes it more difficult for engineers to manage the robust assortment of kinds of foods we are attempting to print.

Another current limitation to 3D printing food is that one can only use dry ingredients which won’t go bad. So most protein and dairy options are off the table. And given that we are (largely) omnivorous mammals, that isn’t going to sit well with what we like to eat and drink.

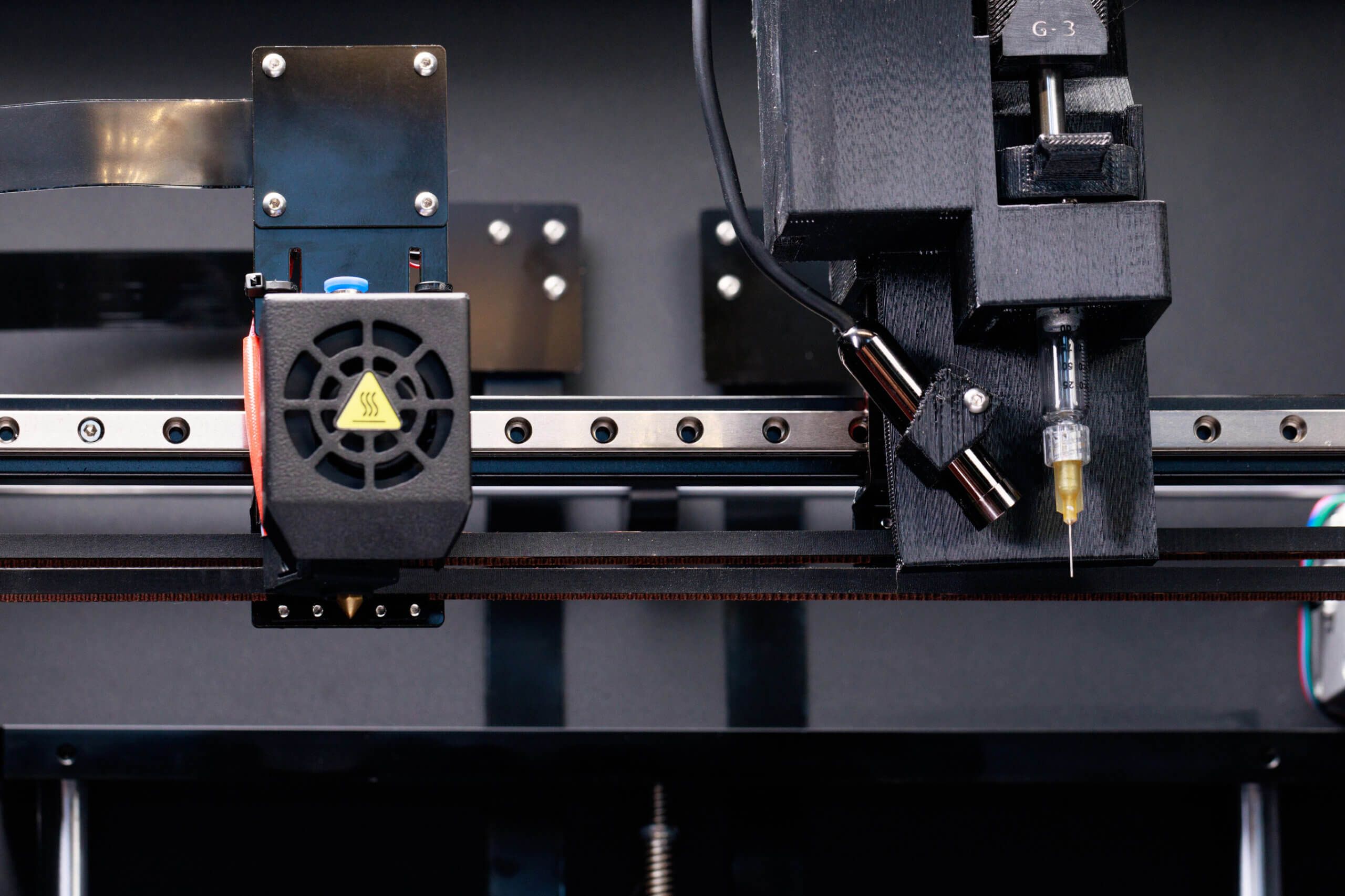

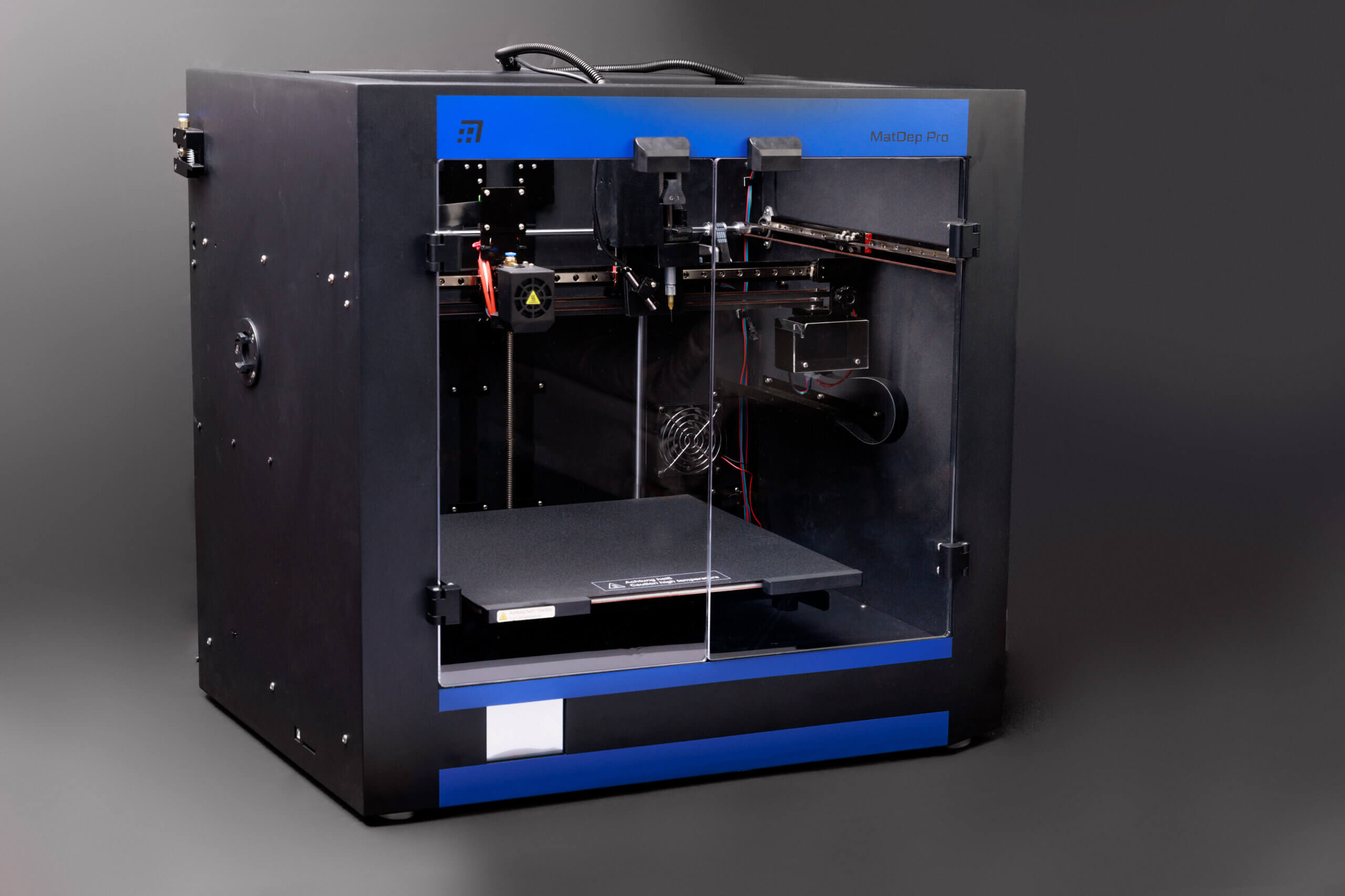

Nano3DPrint

While we aren’t directly involved in the development of 3D food printing technology, we certainly have an interest in such a naturally fascinating topic. Our niche is found outside of the one we discussed today. The first is that we are a 3D printing company which provides affordable, top 3D printers to people who use them for a range of purposes. We supply engineers, researchers, educators, and hobbyists alike with revolutionary 3D printers that have 3D rapid prototyping capability. If you are looking for electronic printing or 3D printed electronics, we have the micro-to-nano scale 3D materials printers which are custom designed for rapid prototyping and printed electronics. We love to consult our clients about their projects, big or small. So if you have questions about our printers, or would like to use us as a 3D printer shop of sorts, we would be happy to provide you with either. Our low cost 3D printers sacrifice nothing in terms of technology or capability, so get in touch with us today! Let us help your idea take shape.