As we navigate the realm of 3D printing, it’s crucial to understand the transformative power of functional materials deposition, a cutting-edge technique that extends the capabilities of additive manufacturing. While traditional methods like Fused Filament Fabrication (FFF) have paved the way, functional materials deposition opens up a world of possibilities that go beyond the creation of simple plastic parts. Materials Deposition incorporates functional pastes and inks into a 3D printed model and allows for diverse applications, including conductive inks for circuit paths or heating structures, efficient printing of chromatic materials, manufacturing of sensors, or precise placement of electrolyte materials for flexible energy systems.

The Essence of Functional Materials Deposition

Functional materials deposition is a revolutionary stride in 3D printing, elevating the technology to new heights. Unlike conventional methods that focus on 3D printing plastic-based structures, functional materials deposition enables the precise printing of functional fluids, inks and pastes onto a myriad of surfaces. This includes not only rigid materials like plastic, glass, ceramics, and silicon but also extends to flexible substrates such as fabric, membranes, gels, thin films, and even paper products.

Applications Beyond the Ordinary

The versatility of functional materials deposition shines through in its applications. This method transcends the traditional boundaries of 3D printing by facilitating the creation of electronic devices, sensors, batteries, and a myriad of other electronics. The ability to deposit functional fluids, pastes and inks onto diverse surfaces empowers designers and engineers to explore innovative solutions across various industries from healthcare to aerospace and beyond.

nano3Dprint’s MatDep Pro: A Technological Marvel

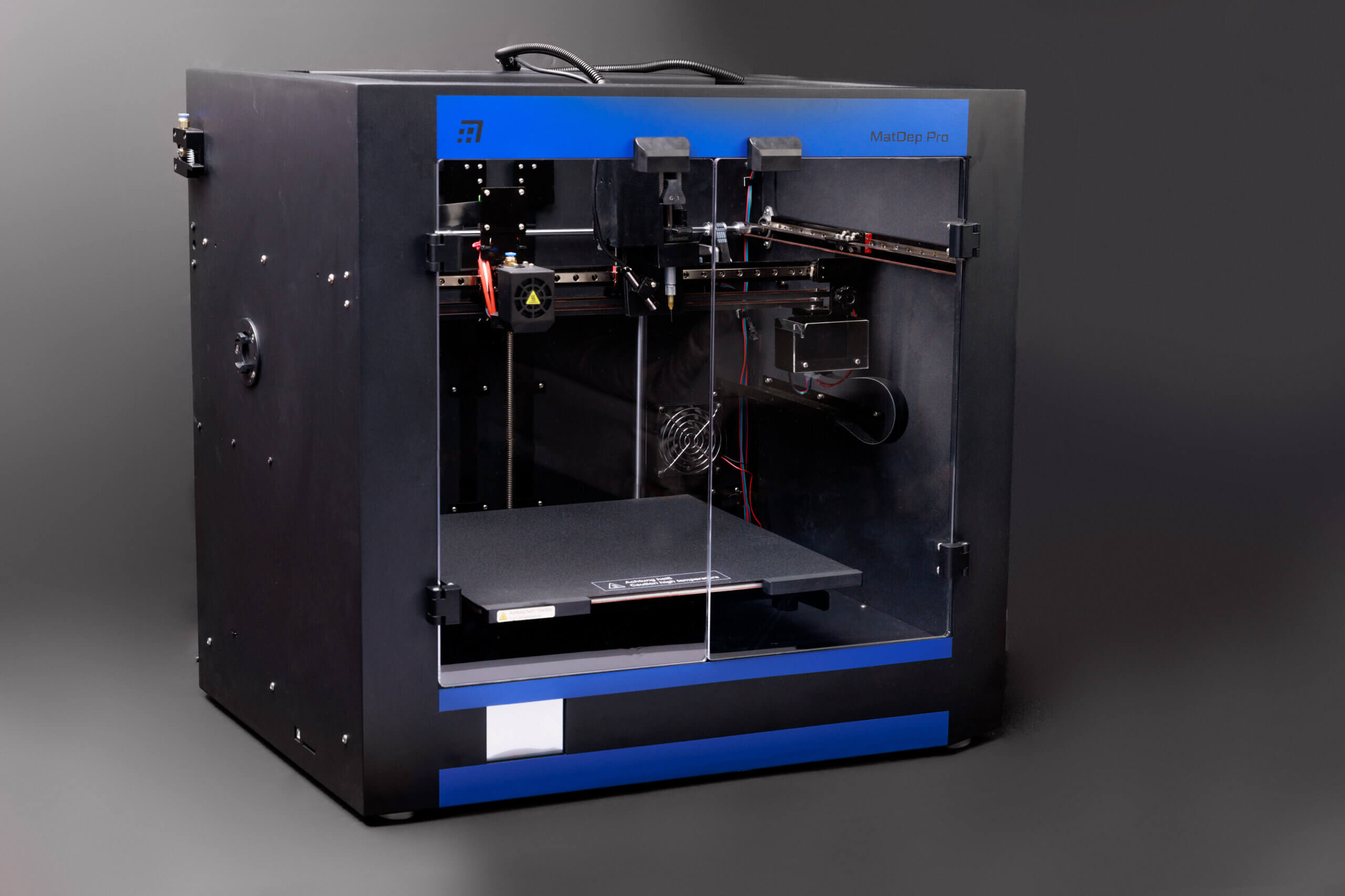

In the dynamic landscape of functional materials deposition, nano3Dprint’s new MatDep Pro is a game-changer in the industry. The MatDep Pro excels in seamlessly integrating conductive and functional inks into a 3D design in a single pass, setting it apart from conventional 3D printing methods.

Unraveling the MatDep Pro’s Capabilities

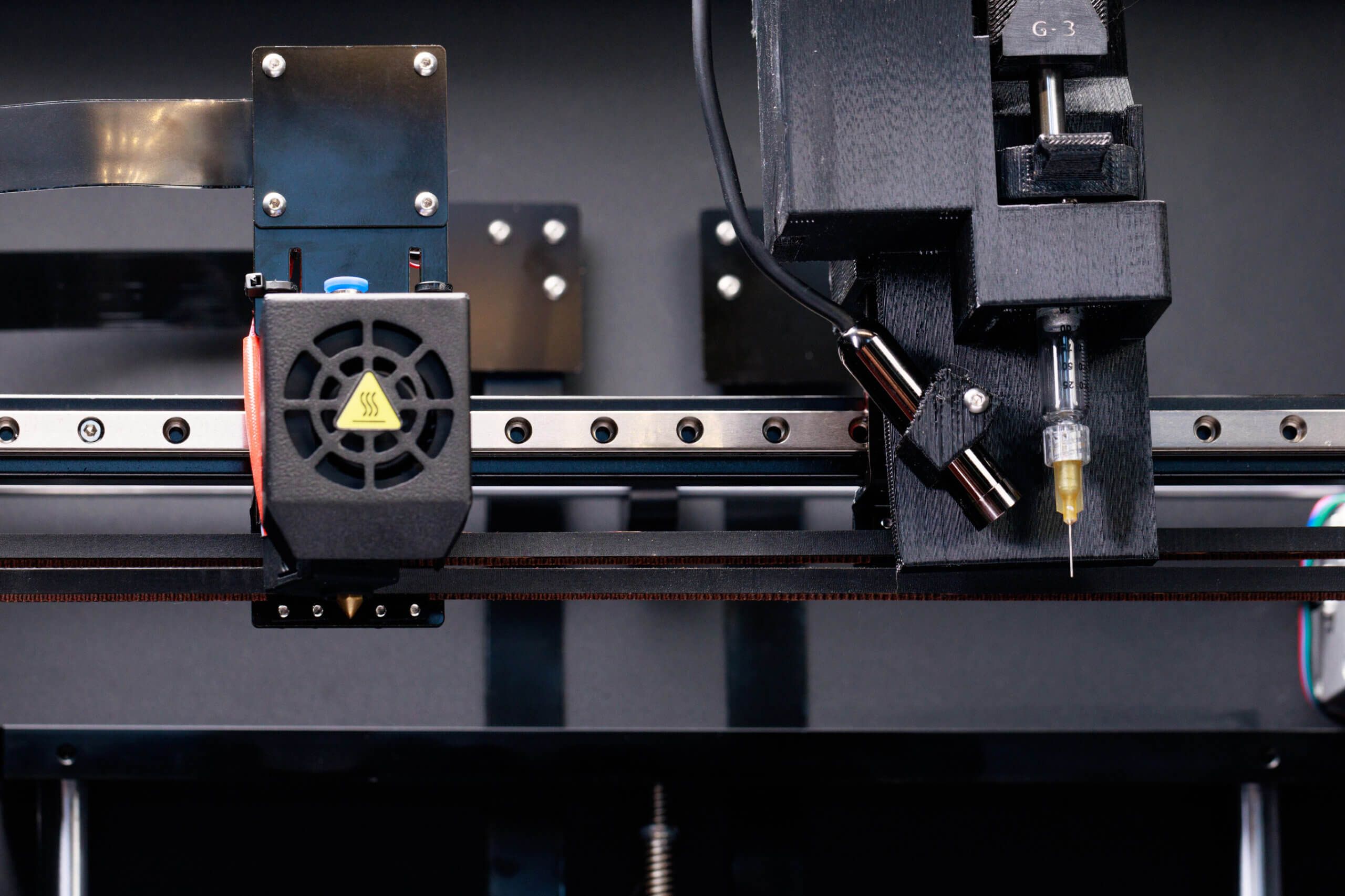

The MatDep Pro introduces groundbreaking innovation with its dual printheads, featuring both an FDM extruder and a Materials Dispensing System, each equipped with independent motion. These two printheads operate autonomously, ensuring precise material placement. Furthermore, the Material Dispensing System can handle highly conductive nano-particle inks (Au, Ag, etc.), versatile pastes (silicone, polymers, etc.), resistive, dielectrics, magnetic, thermo-electric, photovoltaic, graphene solutions, and other materials ranging from viscosities as low as 1 mPa·s to as high as 54000 mPa·s. Users can achieve a 200-micron resolution or 100-micron resolution with specialty nozzles.

Beyond Resolution: Customization and Adaptability

One of the MatDep Pro’s significant advantages lies in its ability to handle functional materials, allowing users to fabricate electronics that seamlessly adapt to diverse shapes and surfaces. This feature unlocks a world of opportunities in fields such as wearable technology, smart textiles, biomedical devices, and conformal supercapacitors. Users can integrate wires and other functional materials directly into the body of their 3D printed parts, ushering in a new era of customization and adaptability.

Pioneering the Future Together

Functional materials deposition 3D printing is not merely a technological advancement; it’s a promise of endless possibilities in the field of electronics and beyond. At nano3Dprint, we stand at the forefront of this revolution, driven by a commitment to design, craft, and assemble the best additive manufacturing technology on the market. As you embark on your journey into the future of 3D printing, we are excited to witness the remarkable innovations that will unfold. Welcome to a future where creativity knows no bounds, and the potential for groundbreaking discoveries is limitless.