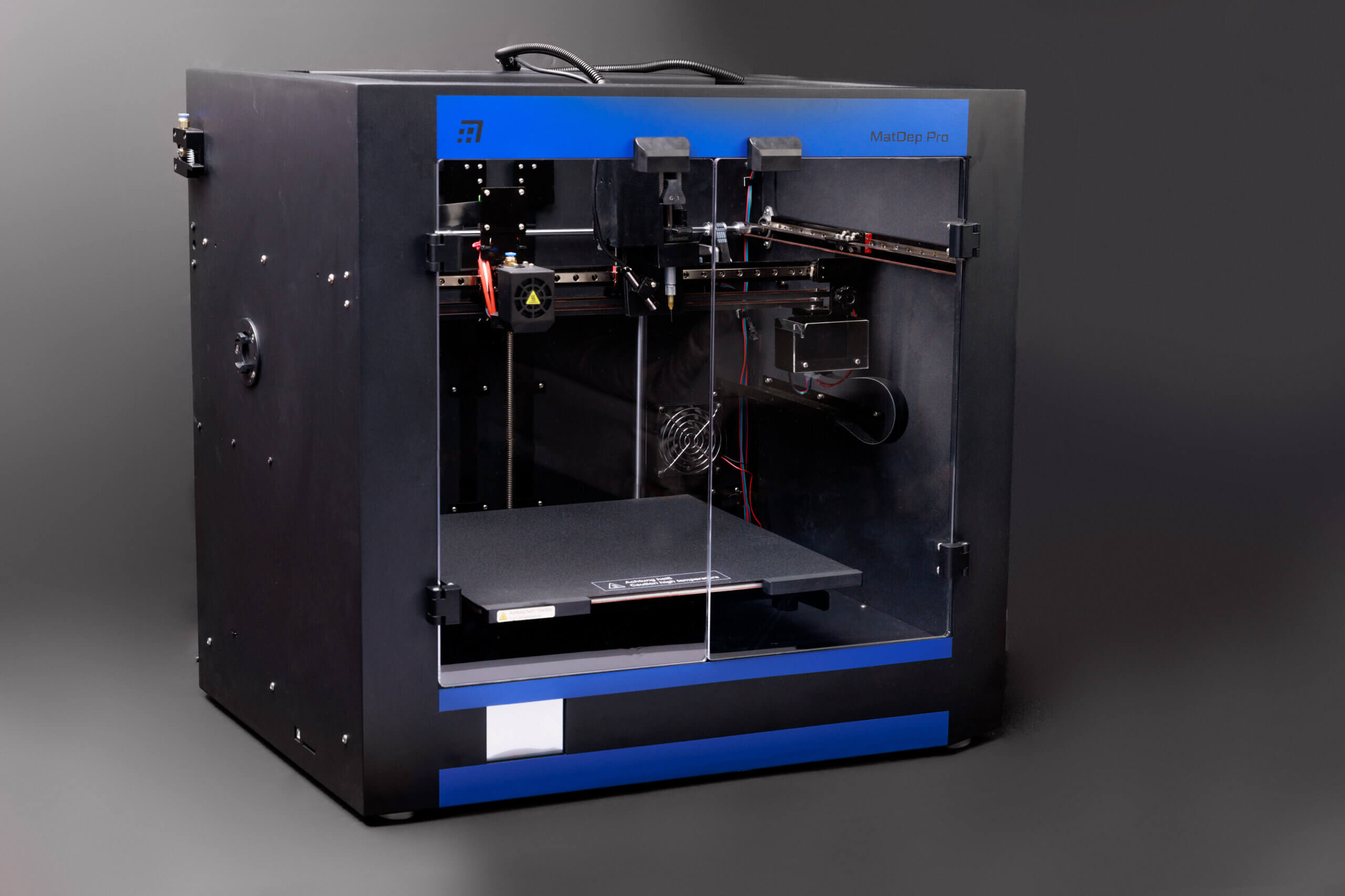

Nano3DPrint has a variety of low cost 3D printers that are reasonably priced for those who wish to harness the rapid prototyping functionality and printable electronics technology without needing a corporate credit card.

In our previous post in this two-part series, we explored the notion that bees are in fact the original 3D printers, and have been utilizing their own type of additive manufacturing (think layer by layer) for thousands of years longer than humanity has. We also took a look at some honey bee-inspired art, in which artists, corporations, and beekeepers combined forces to create genuine honey-bee-made honeycomb art pieces in a variety of shapes and forms.

Today, we will continue to explore the crossover between honey bees and 3D printing. There are more common threads, or cross-pollination (sorry, had to slip it into part two as well) between the two fields than many realize. Continue reading if you are interested in learning about bees that can manufacture concrete, or how 3D printing can assist bees with their honey making process.

Bees Are Quite Important

It has been estimated that bees annually pollinate more than $15 billion worth of U.S. crops such as apples, berries, cucumbers, almonds, and alfalfa. The (actual) cross-pollination that bees facilitate help 30 percent of the world’s crops and an estimated 90 percent of Earth’s wild plants. Suffice it to say that bees are the lifeblood of our not only our global economy, but humanity’s survival as well. It is well-known that bees are disappearing in droves as well. And although that topic is outside the scope of this particular post, we thought it would be worth mentioning that pesticide use, habitat loss, and global warming are the likely causes behind this alarming phenomenon.

A 3D Printed Beehive

Honey is useful and delicious, but harvesting it comes with the price of hassle and resources. Typical ways of harvesting honey cause harm to the harvester and bees alike. One father-son team, comprised of Stuart and Cedar Anderson, have designed an innovative 3D printed beehive that is an improvement, both economically and ergonomically. Printed with non-BPA plastic, the beehive operates, on the whole, in a similar way to organic beehives, with one exceptional modification. The hexagonal cells are made up of columns that connect to a handle external to the hive. Wax seals break apart and the honey flows at the turn of a handle. The honey can easily be collected with this simple yet revolutionary design.

Furthermore, the process of making organic honeycomb is quite taxing on bees themselves. Beekeeper Richard Evatt states that “It takes a lot of energy for bees to make comb. They have to consume a lot of honey. It’s six to eight times the amount of honey to one times the wax.” The article goes on to say that the 3D printed hives will save bees a significant amount of time and energy. 3D printing is vital to this process because in the past we have lacked the precision it takes to replicate a bee friendly home. As it turns out, bees are quite particular about their homes, so the exact specifications that 3D manufacturing can afford is the ideal solution.

If you are interested in more information about 3D printed beehives, check out this great article here.

Bees Making Concrete

It’s not quite as crazy as it sounds. Taking the premise that bees will build their honeycomb hive around whatever confines their environment has to offer, designer John Becker and writer Geoff Manaugh have theorized the concept of genetically modifying bees in order to have them 3D print a durable filament, akin to concrete.

“The ultimate goal would be to produce entire, free-standing architectural forms, but, in the meantime, the bees would be able to construct or repair statuary, architectural ornament, building details and more”, Manuagh told Deezen. Manuagh and Becker envision a world where honey bees could be commandeered to repair structures or even create sculptures by confining a colony within a certain environmental caste. “…or if let loose create gorilla architectural ornament – printing unsolicited additions in urban and natural landscapes”, Becker said in the same article.

Our Take

The premise itself is admittedly a jump in biological technology, at least to our knowledge. Not to mention that we should probably focus our efforts on keeping bees alive and thriving before we try to modify them for our whims, as artful as they may be.

Thus concludes our series on plastic printing and the interesting world of bees. We hope have found it interesting and informative.

Our A1100 and A2200 models are perfect for a small research team or individual needing small volume production of fully functioning electronic devices. Our clients include those in the education, research, and even people looking for 3D printing services for home use. Remember that if you are searching for a 3D printing service online as a one-off, we can assist you there as well.

Our more advanced D4200S model is fully equipped with the cutting-edge nanotechnology that you can come to expect when working with Nano3Dprint. This advanced 3D printer is ideal for printing on the micro and nano scales for objects that utilize printed electronics, prototyping, research and development, and industrial 3D printing application. If you would like more information about our printers and their application, don’t hesitate to reach out to us today! We would love to hear from you and help assist you and your project in any way we can.