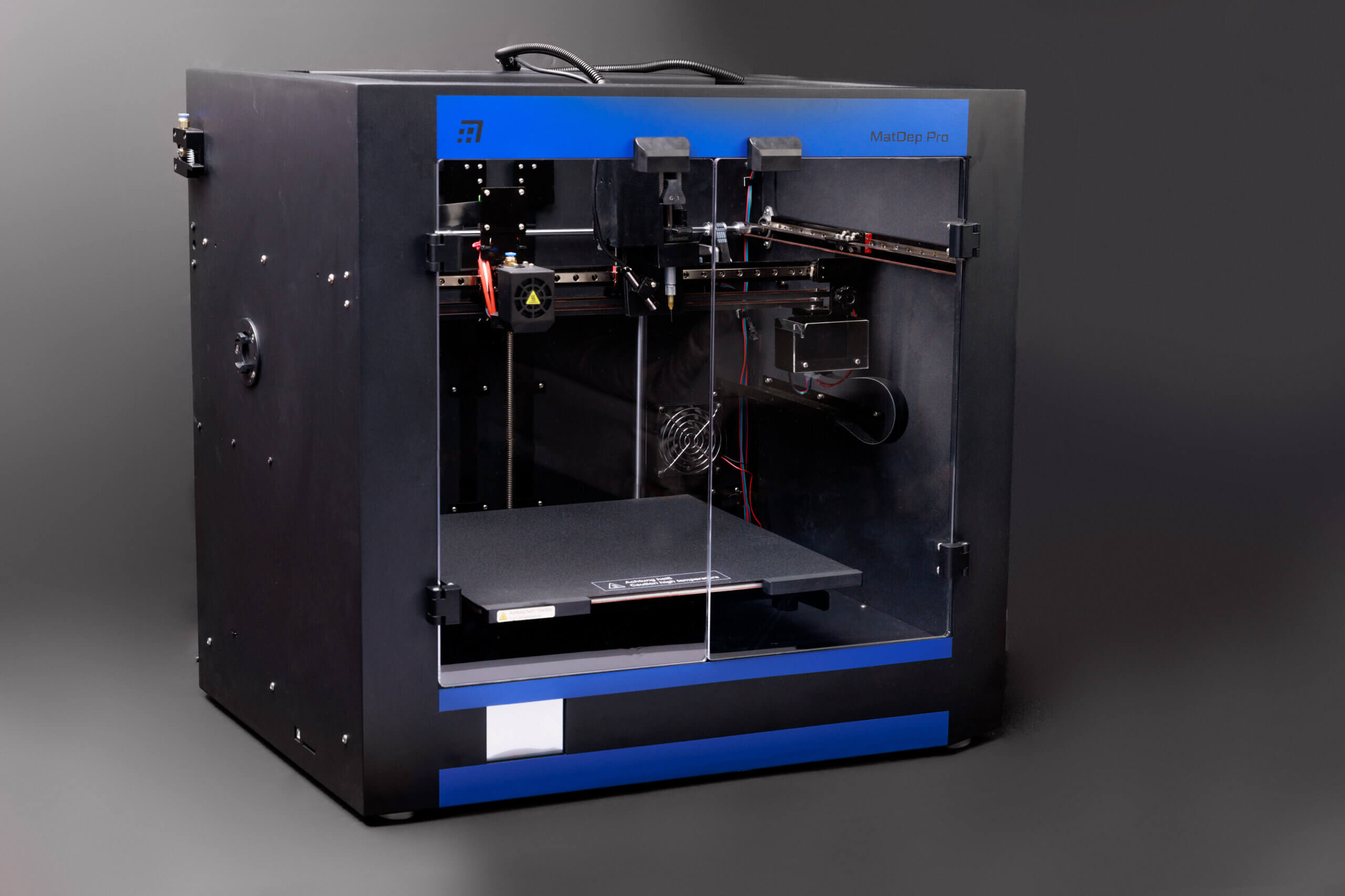

3D printing is a field which is booming at an ever-accelerating rate. With direct digital manufacturer’s newfound ability to legally print objects due to the expiration of relevant patents, we are on the brink of a manufacturing revolution. With an array of plastic and metal items being designed and printed, inventors who were unable to print their previous ideas now can bring their innovations to life. If you are among these 3D printing pioneers or would like to be, consider the unprecedented precision and resolution that Nano3Dprint has to offer. We have printers designed for rapid prototyping and printed electornics and the micro and nano levels. Check out our high resolution additive manufacturing printer, the Nano3DPrint D4200S! In today’s post, however, we will be focusing on the exciting developments of bioprinting and 3D manufacturing.

Bioprinting

3D bioprinting can be defined as the creation of cell patterns utilizing 3D printing techniques and technologies, with the express purpose of ensuring that cell function and viability are maintained within the printed object. This is typically accomplished via a layer-by-layer method, where bioinks contribute to forming a human-tissue-replacement structure. And while all bioprinters are at this point experimental in their development, it is still an industry that has the potential to completely overhaul medicine and biology in its scope and efficacy. Let us begin by analyzing what is actually occurring when we talk about actually 3D printing an organ. We will then look at some of the bioprinting methods, which range from microvalve printing to laser-assisted bioprinting. In the next post in this two part series, we will highlight some of the organ-specific applications that bioprinting is currently exploring.

Living Cells

You may be like many people upon first hearing of this technology, nascent as it may be. People commonly say, “Wait, how could humans print a living cell?” We are glad you asked. The fact is that 3D printers aren’t creating living cells out of nothing, or “ex nihilo”, if you will. Any tissue in your body is made of various cell types (think bladder cells or bone cells and the like) are extracted from a subject and are then put through a cultivation process. This process is administered until there is a sufficient volume of cells to make the “bio-ink” which is then loaded into the printer, ready to go. It should be noted that this process isn’t always possible given the many types of cells that exist in the human body. Adult stem cells can be used as an alternative in order to develop the desired cell type, which would then become bio-ink.

Life finds a way

Beyond the artificial development of living cells, there also exists a synthetic adhesive which is incorporated into the bio-ink. The solution itself is typically some sort of dissolvable gel or collagen scaffold that cells attach to and grow upon. It’s essentially a framework for cells to develop, akin to the hexagonal format employed by bees to make a hive. Remarkably, scientists have observed that some cells have the ability to take on the appropriate positioning to thrive sans the synthetic scaffolding. But how does this happen? We could probably allocate a blog or two about that topic alone, but for the purposes of this post let us say that cells utilize innate functionality to seek out and find similar cells, kind of like people do, actually. Cells naturally know where to go. Scientists harness this observed behavior, if you could call it that, and guide the cells along to their final destination, using the manmade framework.

Printing

The process of 3D printing involves more than this bio-ink solution, however. Scans are taken from a subject and are combined with a complex system of digital designs to precisely deposit cells in the appropriate location. The process usually takes several hours, depending on the organ being printed. The printer applies the bio-ink, layer after layer, until the 3D printing process is complete.

Common Bioprinting Methods

This is far from an exhaustive description of each 3D bioprinting method, but for the scope of this post it will have to suffice.

- Tissue Fragment – A combination of bioprinting that involves biological self-assembly. Employing this technique harnesses the natural function of tightly grouped tissue pieces to fuse together, in a process known as tissue fluidity. This process was founded on the principle that “nature knows best”, drawing from principles of developmental biology. In more than a few ways, this approach can be viewed as a distinct bioprinting concept, as opposed to simply being an alternative bioprinting technique.

- Inkjet – Also known as drop-based bioprinting, inkjet involves the process of making cell-based constructs with singular “drops” of a specific material which is then combined with a cell line. The inkjet approach can be loosely categorized into continuous inkjet (CIJ) and drop-on-demand inkjet (DOD).

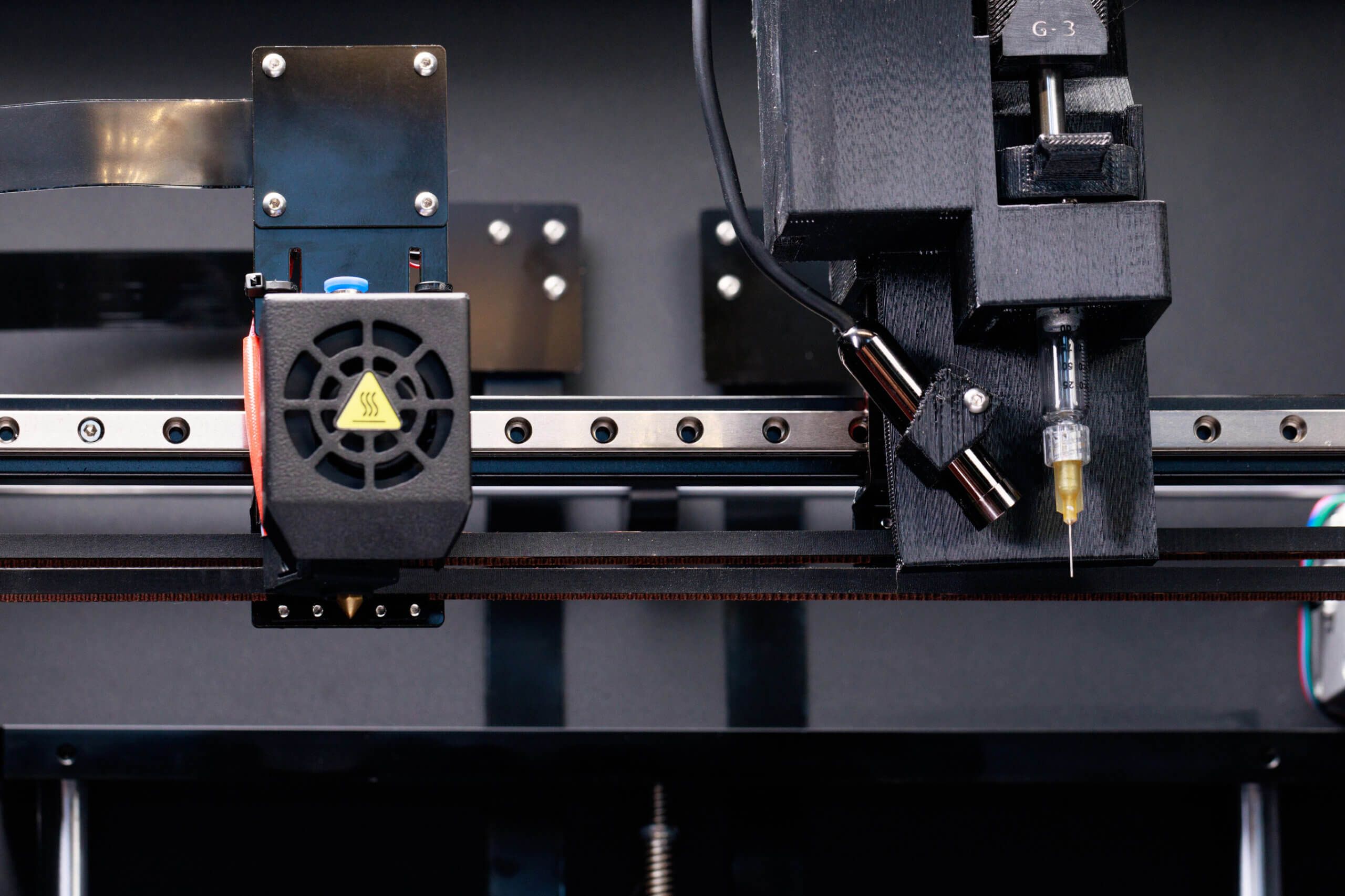

- Extrusion – A traditional approach that forces continuous filaments of a given material through a hose of sorts in order to produce a 3D printed item. The used material is usually made of an extremely viscous cell-laden gel.

- Laser-assisted bioprinting – Among the pioneering approaches in bioprinting, this method involves a weakly focused laser beam acting as an optical trap able to manipulate the movement of particles in a given solution. Laser-assisted bioprinting has been used for layering multiple cell types.

- Microvalve printing – Microvalve printing is also a droplet-based “deposition mechanism”. The process entails forcing fluids under consistent pneumatic pressure, dispensing the fluid from a nozzle tip that opens and closes. This mechanism can be controlled mechanically, electrically, or even magnetically. The most common application for microvalve printing is in the field of robotic spotting technologies where DNA, antibodies, and other biomaterials can be deposited onto glass slides via pin-style printers.

Beyond Bioprinting

We hope that you’ve enjoyed this far-from-exhaustive foray into the fascinating world of 3D printing and bioprinting. Among the many 3D printed objects that you can think of, literally printing human skin, a kidney, or a hip bone ranks pretty high up there. When it comes to more practical 3D printer technology, we at Nano3Dprint are on the cutting edge in our own right. For example, our A1100 and A2200 printers effectively democratize inventorship by lowering the barrier for 3D printing prototyping and small volume production of fully functional electronic devices for both education and home use. Hence, if you are a researcher looking to affordably invest in a printed-electronics-ready 3D printer, we have what you are looking for. Conversely, if you are an educator of some sort looking to share the power of 3D printers with others, we ask you to consider putting our printing services to work in your classrooms. It doesn’t matter if your students are actually inventing 3D printed electronics or are simply manufacturing 3D printed gifts, we would love to be involved. Whether you fit into one of the above categories or not, Nano3Dprint is doing some wonderful things in the world of novel 3D digital printing and 3D printer uses. With our variety of printers utilizing revolutionary technology in the realms of functional inks and conductive filament, our printers have the capability to handle most anything you can think of creating in the world of printed electronics. Watch this space for part two of our series on bioprinting. Our next post will focus on specific organ printing and application!