In Review

In our previous installment, we explored some of the 3D manufacturing initial advancements within the automotive industry. We talked about how in 2013 the very first CAD file for a functional and printable handgun was released by a group called Defense Distributed. Although it was promptly taken down by the U.S. Department of State, there were over 100,000 unique downloads of the printable handgun file in just a two day span. We also covered the very first 3D printed car parts from companies like Glickenhaus and Local Motors, manufacturing the original titanium exhaust pipe or even replica dashboards from vintage 1960 Ferrari models. Next was the incredible Strati, which has shown remarkable innovation in regards to improving the safety of driving (because of new material manufacturing), and also the exciting idea of melting down a crashed vehicle (everything aside from the engine and suspension) and simply reprinting a new vehicle from the melted substance! If you’re interested in all the details, check out the full article here. In part two, we will be covering some of the more recent 3D printing techniques, specifically applied in the automotive sphere.

The Government Gets Involved

With all the buzz going around about 3D printed cars, the US Government couldn’t help but get in on the action. At the Oak Ridge lab, governmental engineers used its cutting-edge Big Area Additive Manufacturing Machine, or BAAM, to design and print an electric roadster based on the classic Shelby Cobra. In the same way the Strati was 3D printed, the vehicle is made almost exclusively from carbon-fiber reinforced plastic, including the entire body and chassis. If you are interested in seeing the making of the Oak Ridge Cobra, check out their video at the bottom of the here. With the US Government getting involved in this industry, it wasn’t long for some of the big boy OEMs to follow suit.

Beyond Plastic

With the US Government and big time Original Equipment Manufacturers such as Fiat Chrysler getting involved in the 3D manufacturing game, it followed that with more funding available, the more opportunity for technological advancements would arise. For example, most all of these previous examples discussed have been within the framework of rendering auto parts in different parts of plastic. More recent advances have begun to explore other additive materials, such as metallic powder to create metal objects. In early 2015 the Federal Aviation Administration authorized the first chrome-alloy housing for use in General Electric jet engines. This chrome-alloy piece goes down as the original 3D printed part approved for use in aviation. Diverting from the industry norm of using superheated plastics, the General Electrics chrome-alloy piece utilized a pioneering technique in which metal powder is fused together by a laser, building upward to 3D print a solid metal object. This is not only a significant advancement from a materials perspective alone, but also a financial 3D prototyping point of view. It allows companies like Fiat Chrysler to prototype their parts in metal instead of having to put up with the lengthy development time and unreasonable costs connected with the outdated process of hand-making prototypes.

BMW has also decided to get in on the fun. In April of 2015, they announced that it already had 3D manufactured five hundred aluminum water pump wheels, a fascinating 3D printer use. BMW’s engineers utilized the Selective Laser Melting (SLM) process in this series. The 3D printer applies .05-millimeter individual layers of the metal powder coating to a processing plate. Next, a laser beam fuses the powder at the appropriate points within an inert environment, forming a durable aluminum layer. BMW goes on to explain that the expertise required to perform SLM procedures is much greater than the more commonly used plastic filament 3D printing, utilized in many consumer-based industries. In a press release, BMW had this to say about their achievement: “The high-precision component, which is subject to high stresses, consists of an aluminum alloy and has previously proven its worth in the tough environment of motorsports: Without exception, all pump gear works flawlessly, confirming BMW’s leading role when it comes to additive production methods.”

Conductive Inks

Before we get into the weeds too deeply with Printed Electronics and the automotive field, we need to discuss the importance of conductive inks. Conductive inks are inks that result in a printed object which conduct electricity. Typically it’s made by infusing graphite or another conductive material into ink. The market for conductive filaments has been applied in vehicles in was such as window defoggers and even car-seat heaters.

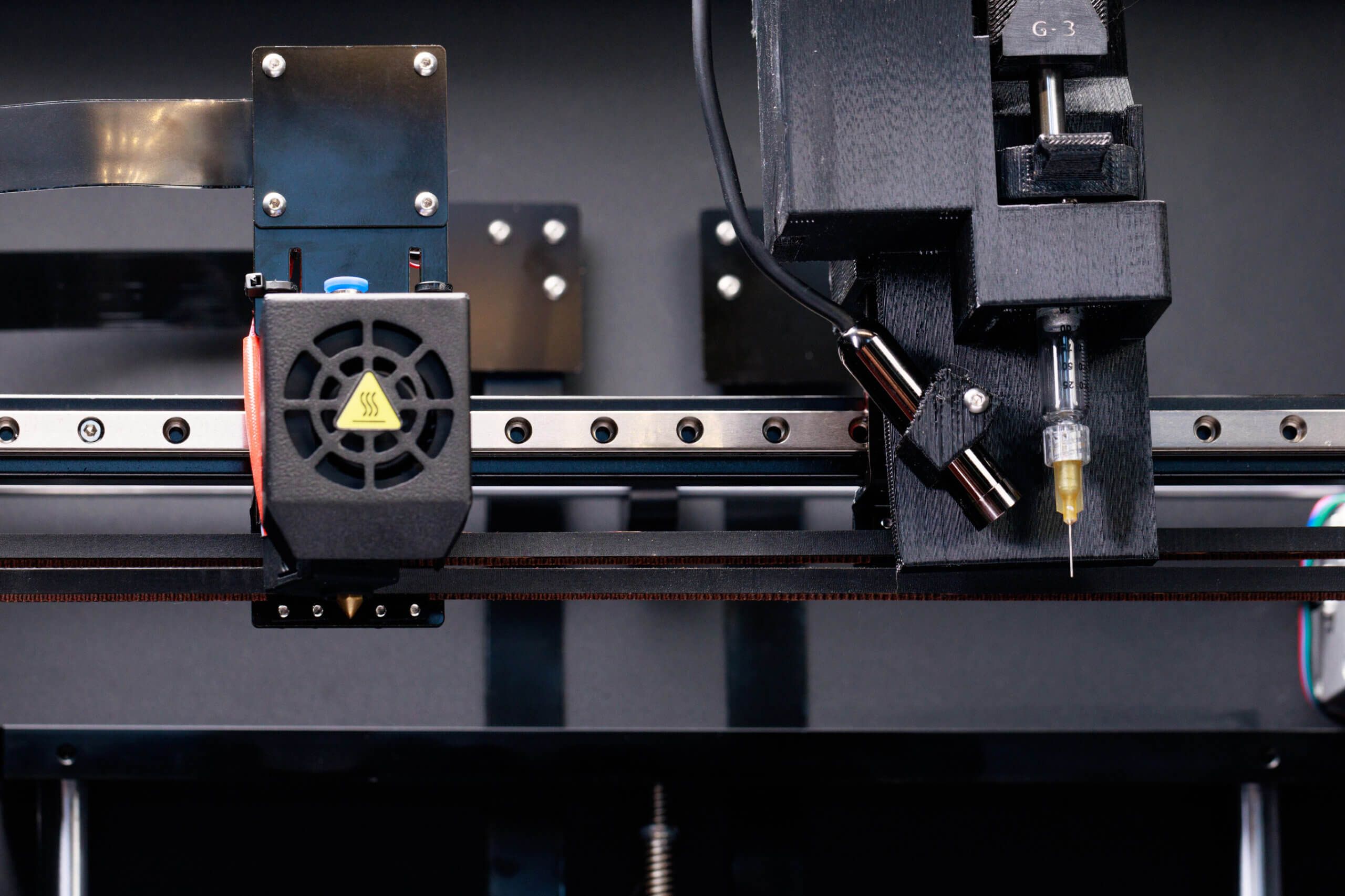

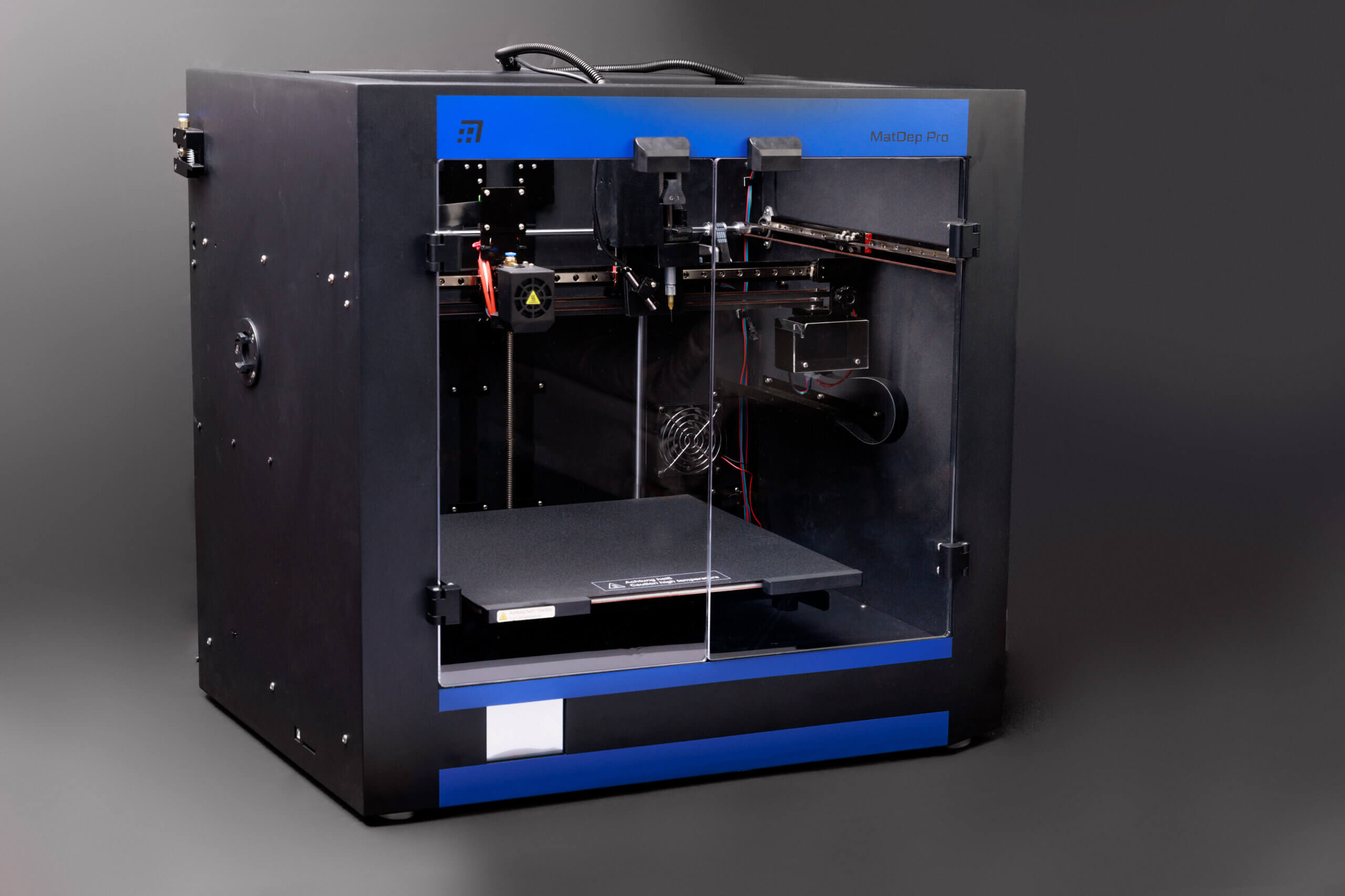

We are very familiar with conductive inks, or filaments, at nano3Dprint. We are proud to create 3D printers such as the A1100, with the intention of providing engineers, scientists, and even hobbyists the capability to prototype their desired object with fully functioning electronic devices for education and even home use. We have developed the ability to dispense functional conductive inks at both the Micro and Nano scales. We have various 3D printers designed for a wide range of 3D rapid prototyping and manufacturing, so please don’t hesitate to get in touch with us so we can be of assistance in your decision-making process. In the next and final installment of this three-part series, we will go more in depth about Printable Electronics and their automotive application, especially in regards to structural and mold electronics, fields which are expected to grow significantly in the next decade. Keep an eye out for our final post in this series about 3D printing and automotive applications.