3D printing may have been around for longer than you think. Back in 2009 (almost ten years ago!), the Fused Deposition Modeling (FDM) patents expired. Prices for FDM printers fell from $10,000 to to sub-$1,000 prices. Subsequently, 3D printing essentially went “viral”, which led to many believing it was a brand new innovation due to widespread media coverage. During this time, a new wave of of consumer-facing 3D manufacturers emerged as a means for accessible 3D fabrication and printing for the public.

Early 1980s

But in reality, 3D printing has been around since the first attempts in 1980. Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute published the first very first account of a functional photopolymer 3D rapid prototyping system. Dr. Kodama is credited as the first person to promulgate a layer by layer technique for manufacturing, a predecessor to Stereolithography, which involves a photosensitive resin polymerised by UV light. However, Dr. Kodama failed to file the requisite patent before the deadline.

Stereolithography

Around four years later, Charles Hull deposited the first patent for Stereolithography (SLA) in 1986. To ensure we are all on the same page concerning 3D printing processes, stereolithography is a resin 3D printing or additive manufacturing process that incorporates a portion of photopolymer resin is able to be cured. The build plate moves vertically in small increments, and the liquid polymer is then exposed to light. Finally the UV laser draws a cross section layer by layer, over and over, until the model is created. Hull founded 3D Systems Corporations, and they released the SLA-1 about a year later.

SLS Technology

In 1988, Carl Deckard patented a new additive manufacturing 3D printing process called Selective Laser Sintering, or SLS. SLS employs a powder bed fusion process to manufacture 3D parts. This material (usually nylon) is transferred from holders containing the powder onto the build stage in the processing chamber with a recoating tool, which is found inside the SLS machine. Next, a laser is moved to the platform, tracing cross-sections of the model onto the powdered material. In its essence, SLS technology involves the exposure of micro-particles of materials like glass or ceramics to the heat of a high-powered laser, which fuses the materials together to form a 3D object.

Deckard and his Mechanical Engineering professor patented the SLS process and in 1989 founded one of the first additive manufacturing companies called Desk Top Manufacturing. Since then, major patents have covered the SLS process, which has largely contributed to the inability of major companies accessing the SLS 3D printing process. Because of the lack of competition, SLS companies have been priced out of the market, generally speaking. Today, your average SLS machine can cost you upwards of $250,000, meaning many individual consumers (and businesses) aren’t able to access the Selective Laser Sintering technology.

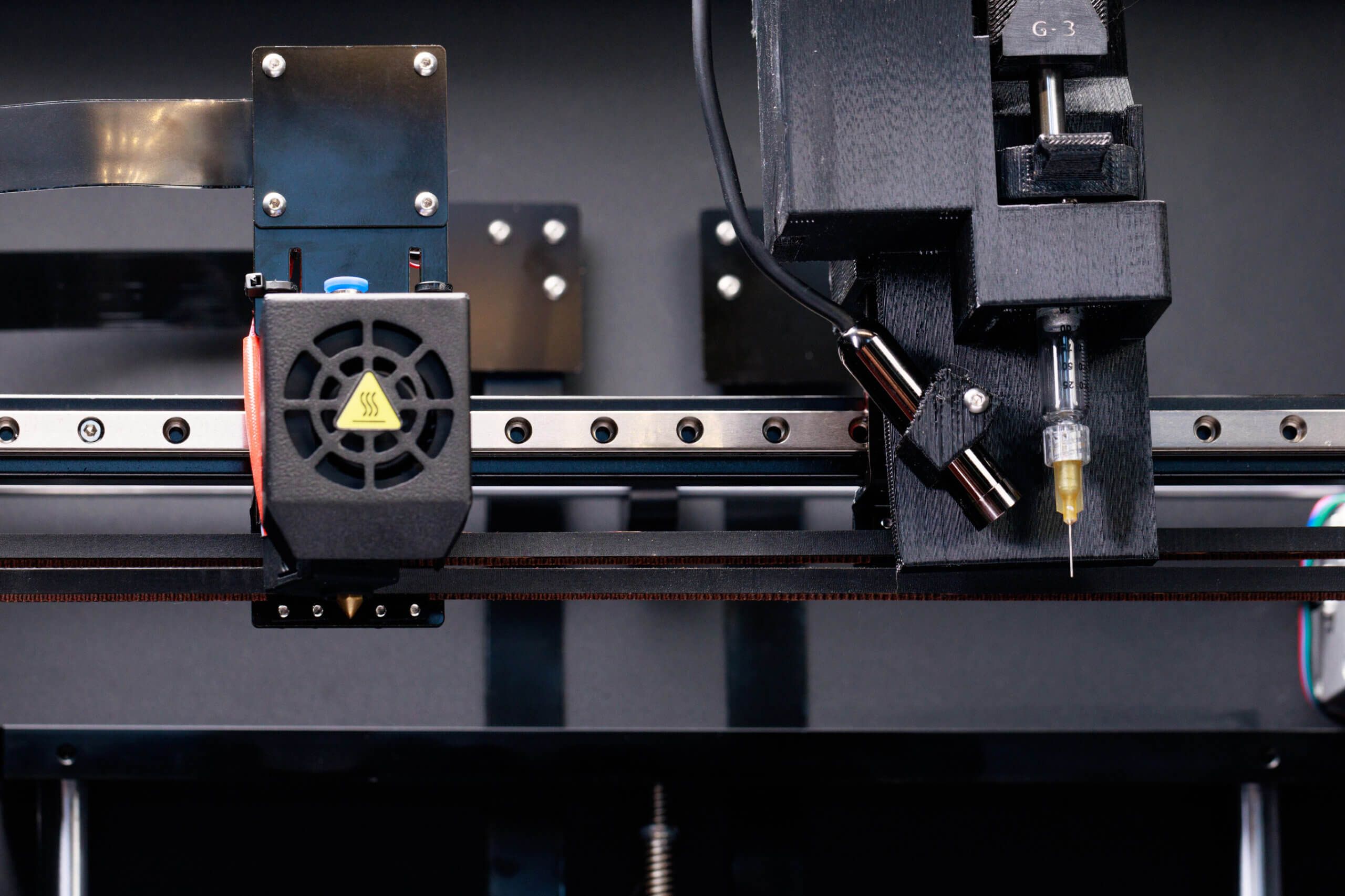

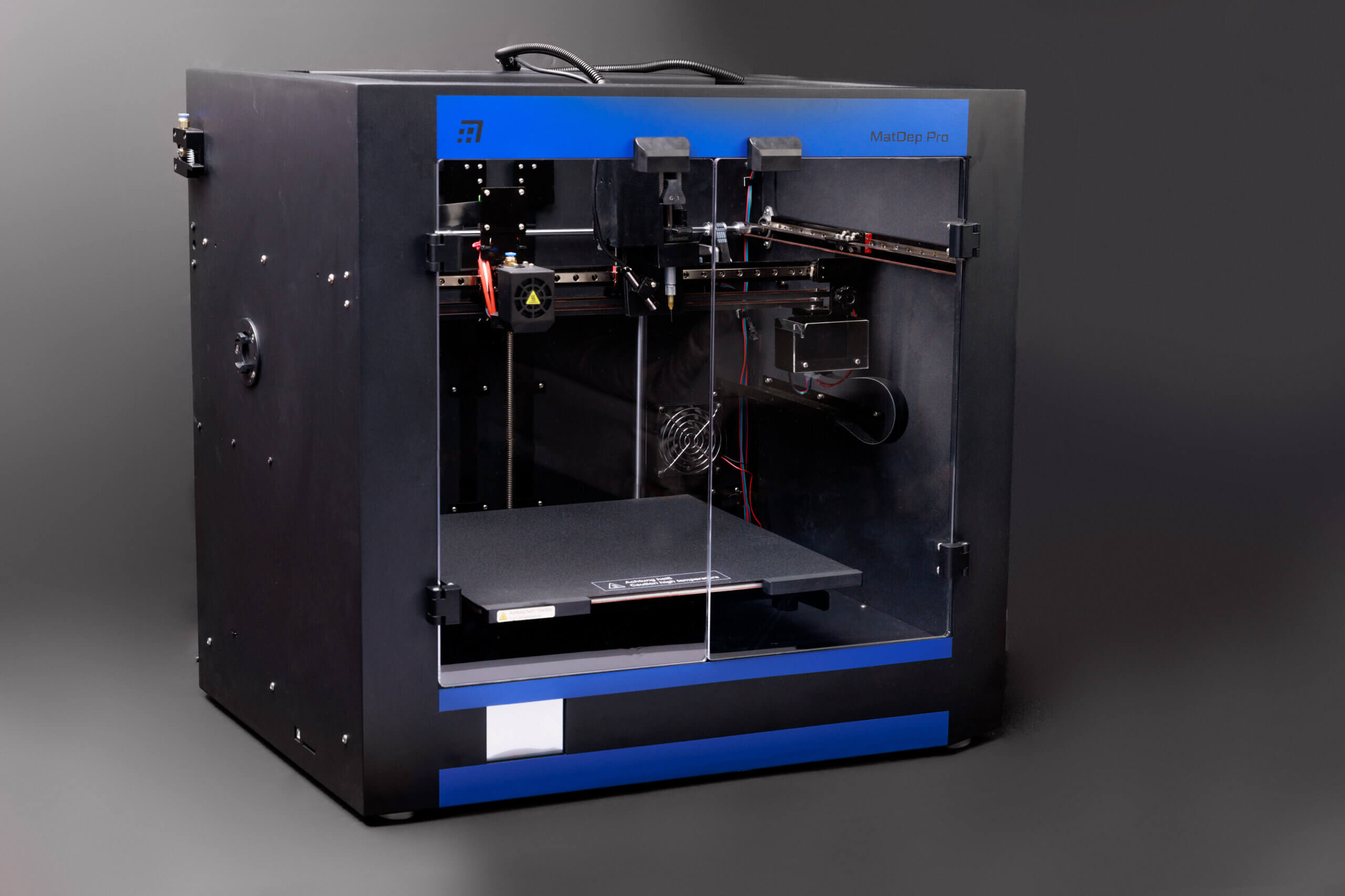

Fused Deposition Modelling

A contemporary of Charles Hull, Scott Crump, was developing a different type of 3D printing technology. Fused Deposition Modelling is an additive manufacturing technology. FDM works on a additive principle of laying down thermoplastic filament, which is heated to its melting point and then laid, layer by layer, creating a 3D object. FDM printers involve two types of materials, modeling material and a support material. The modeling material will eventually become the finished object, while the support material acts as a sort of scaffolding to hold up the object while it’s in the process of being printed.

Fused Deposition Modelling is still quite popular today. In fact, FDM has become the most popular 3D printing technology and method used in the whole world. For businesses, inventors, or even hobbyists, FDM printers are often reasonably priced, which also has contributed to their popularity. For example, the Stratasys’ Mojo costs just under $10,000.

Watch This Space!

We’ve covered the original three 3D printing technologies, SLA, SLS, and FDM. In future posts we will discuss more modern methods and applications, such as electronic printing and nano 3D printed objects. We at Nano3Dprint are excited to tell you more about contemporary techniques and uses, such as prototyping, bioprinting, and tissue engineering. So if you are a hobbyist, engineer, or a decision maker for your business, watch this space!